Waterjet

& Flash Cutting

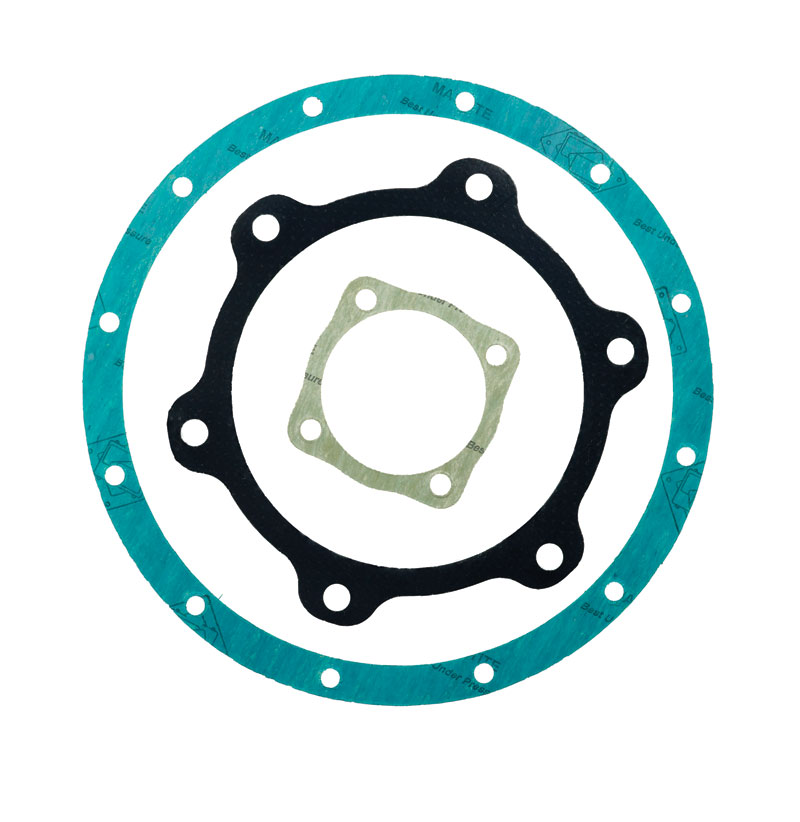

Greenville Industrial Rubber & Gasket offers you the finest in precision shape cutting with ultra-high-pressure waterjet cutting service.

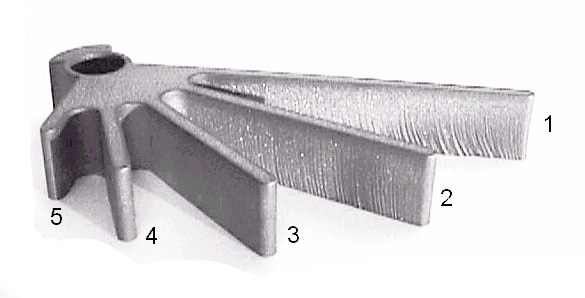

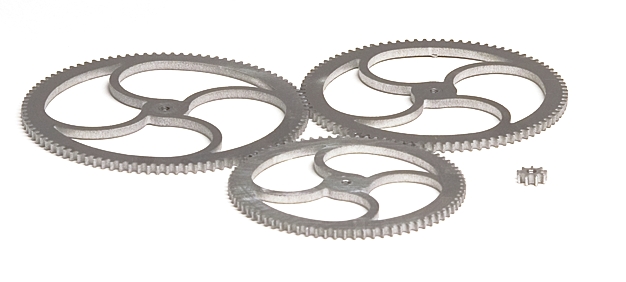

Our advanced waterjet cutting machine offers you seamless access to the finest waterjet cut parts crafted from virtually any material available on Earth. With this technology, you receive ultra-accurate parts that are easily revisable and repeatable, ensuring precision and consistency throughout each production run. Additionally, these parts can be efficiently catalogued with a part number or description that you control, allowing for streamlined inventory management and tracking. At GIRGCO, our waterjet cutting service is dedicated to providing our customers with the very best product in a timely manner, ensuring accuracy and satisfaction. The advantages of our state-of-the-art waterjet cutting machine translate into significant benefits, which directly contribute to the creation of higher quality parts while generating minimal waste in the process! It’s important to note that we are an ISO 9001:205 certified company, which underscores our commitment to quality. Rest assured, your cut parts will be produced in accordance with the stringent requirements necessary to maintain this esteemed certification.

WE CAN IMPORT YOUR DRAWINGS, CREATE NEW CAD FILES FROM SKETCHES OR SAMPLES, OR WORK WITH YOU TO CREATE THE PERFECT PART.

UNMATCHED DIVERSITY! WE CAN CUT 1/16" THICK RUBBER AND SWITCH TO 4" THICK STEEL WITH NO CHANGE IN TOOLING.

REPEATABILITY & FLEXIBILITY: GET THE SAME SHAPE EVERY TIME YOU ORDER, OR MAKE ADJUSTMENTS AS YOU GO.

MINIMIZED MATERIAL WASTE TRANSLATES TO LOWER COST!

ADJUST EDGE QUALITY AS PER YOUR REQUIREMENTS.

NO HEAT-AFFECTED ZONES.

MINIMAL KERF

EXCELLENT TOLERANCES

For soft materials, no equipment can precisely cut faster than the Atom Flash Cutter. !

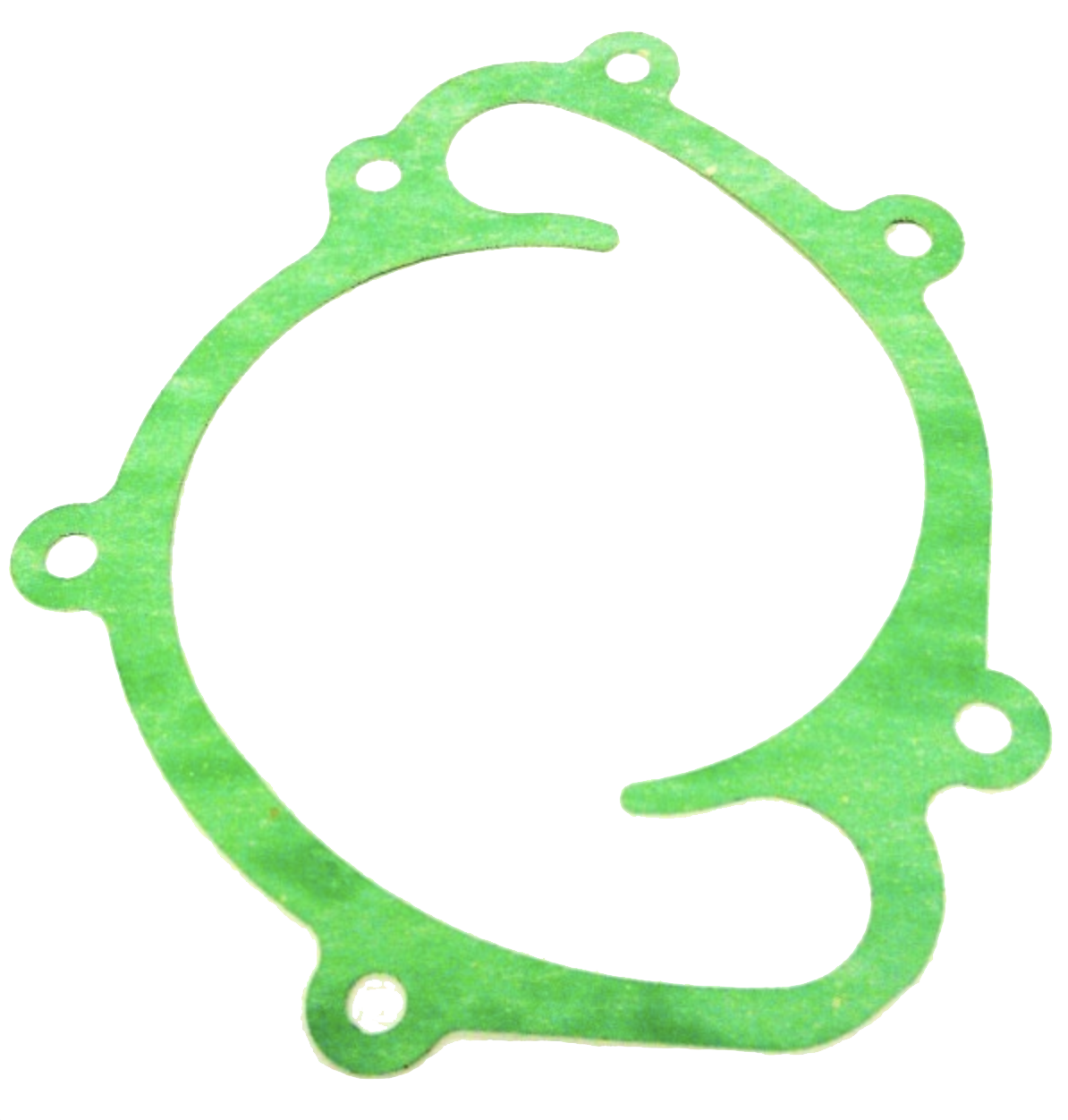

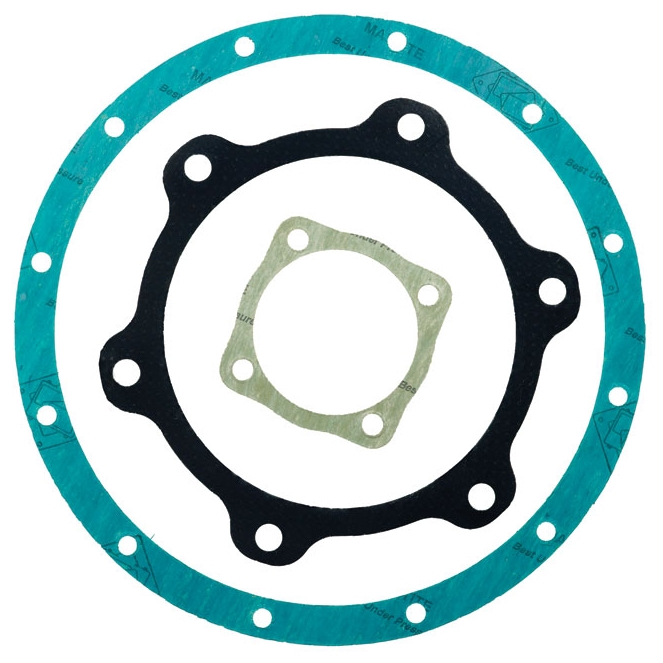

Similar to our waterjet cutting machine, our new flash cutter can fabricated custom gaskets with lightening fast speed. No individual tooling is required for this gasket cutting machine to cut soft and semi-rigid materials. Knife cutting systems guarantee quality, reliability and performance, just like our waterjet. However, flash cutting is a faster and less expensive process. The flash gasket cutter utilizes a CNC control precisely cut material from .001” - .750”, while the material is pulled with negative air pressure to lie flat on the table. It allows for custom options and faster production turn-around times. The flash gasket cutter give our clients access to quick prototypes or large production runs. The flash cutter uses an overhead projector to give our gasket maker the ability to perfectly nest the gasket products to maximize material efficiency and provide a lower cost product. Remember, we’re an ISO 9001:205 certified company! Your gaskets will be produced in accordance with the requirements necessary to maintain this certification.

WE CAN IMPORT YOUR DRAWINGS, CREATE NEW CAD FILES FROM SKETCHES OR SAMPLES, OR WORK WITH YOU TO CREATE THE PERFECT PART.

UNMATCHED SPEED! GASKETS CUT AT A BREAKNECK PACE!

REPEATABILITY & FLEXIBILITY: GET THE SAME SHAPE EVERY TIME YOU ORDER, OR MAKE ADJUSTMENTS AS YOU GO.

MINIMIZED MATERIAL WASTE TRANSLATES TO LOWER COST!

WATERJET AND FLASH CUTTER DRAWINGS INTERCHANGE!

DIELESS CUTTING… NO TOOLING CHARGES.

EXCELLENT TOLERANCES